A powerful manufacturer of high-end semiconductor laser products

A powerful manufacturer of high-end semiconductor laser products

A powerful manufacturer of high-end semiconductor laser products

1.Laser direct imaging(LDI)

Maskless lithography can be achieved through LDI, which has many advantages in imaging resolution, alignment accuracy, product yield, and automation, and is rapidly replacing traditional mask exposure production methods. With LDI, 3D printing of polymers, ceramics and other materials is also possible.

Han’s TCS can provide 375nm/405nm lasers for manufacturers of LDI equipment. Our unique design and production process of our lasers can ensure the stability and uniformity of exposure energy, the maximum power of 100W, compact design, easy to maintain and repair, Based on high quality chips, we can ensure the stability and uniformity of exposure energy, advanced technology, excellent performance. We have many LDI equipment customers and rich industry application experience.

2.Solid-state laser and fiber laser pump sources

Han’s TCS provides 808nm, 878.6nm VBG, 976nm VBG and 981nm VBG pumping source products for solid-state laser and fiber laser manufacturers, which can meet the needs of nanosecond, picosecond and femtosecond laser manufacturers. About the 878.6nm VBG products, we have 40W, 70W, 100W, 120W, 180W and other power grades, which can be used for high power nanosecond lasers and picosecond laser products. The product has good spot uniformity, high efficiency of pumping Nd:YVO4 crystal, wide wavelength locking power range, proven by many customers at domestic and abroad for many years, stable and reliable, to meet the needs of customers 7 × 24 hours industrial production.

3.Laser plastic welding

Han’s TCS supplies semiconductor lasers to manufacturers of laser plastic welding equipment, meeting the needs of simultaneous laser welding, laser contour welding and Quasi-simultaneous laser welding. In particular, our company has a obvious advantage in the supply of simultaneous laser welding laser systems.

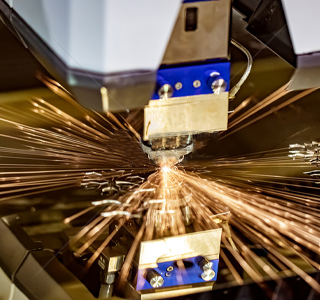

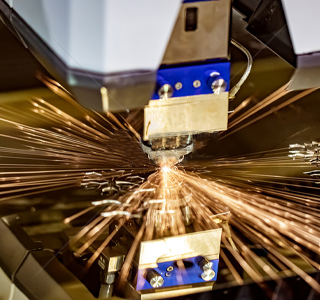

4. Blue laser

In recent years, fiber lasers have developed rapidly and are widely used for cutting and welding materials such as carbon steel and stainless steel. However, this NIR laser absorbs little when welding metal materials such as copper and gold, easily sputtering and have air holes, and requires a high laser power. However, the shorter wavelength offers a much better absorption match for welding and 3D printing certain materials. The blue laser is able to perform welding more quickly than infrared ones, especially for colored matals like gold, copper, and other reflective metals.

In order to meet the demand for blue laser in the market, Han’s TCS has launched blue semiconductor laser after technical research and solving various difficulties. The wavelength is 450nm, and the power 50W, 100W, 200W, 500W and others available. Han's TCS was using single-emitter diodes instead of diode bars, so that the diodes could deliver better brightness, higher thermal stability and long-term stability. The products have run long-term aging tests, with excellent quality and stability, and can be used for welding, cladding and laser additive manufacturing of copper, gold and alloys containing those metals.

Address: No. 8, Liangshuihe 2nd Street, Beijing Development Area, Beijing, China.

Tel: 86-10-67808515

Email: sales@tc-semi.com

Tianjin factory address: No. 117, Yongjin Road, Beichen Economic and Technology Development Area(BEDA),Tianjin, China.

Tel: 86-22-26876901-6006